- Accueil

- Volume 19 (2015)

- numéro 3

- Impact of drying and heat treatment on the feeding value of corn. A review

Visualisation(s): 3422 (60 ULiège)

Téléchargement(s): 342 (1 ULiège)

Impact of drying and heat treatment on the feeding value of corn. A review

Notes de la rédaction

Received on January 21, 2014; accepted on February 5, 2015

Résumé

Impact du séchage et des traitements thermiques sur la valeur nutritionnelle du maïs (synthèse bibliographique)

Introduction. Le maïs est la céréale la plus cultivée dans le monde. Principale céréale utilisée pour l’alimentation de la volaille, les grains de maïs fournissent aux animaux une grande partie de leur énergie métabolisable et une quantité non négligeable de protéines. Cependant, lorsqu’ils sont soumis à des températures élevées, comme au cours du séchage, leur valeur nutritionnelle peut significativement varier. La présente synthèse bibliographique fait le point des connaissances actuelles sur les changements s’opérant dans le grain au cours du séchage et des traitements thermiques à haute température et qui peuvent affecter la valeur nutritionnelle des grains de maïs.

Littérature. Les études ont montré qu’au cours de ces traitements thermiques, des changements structuraux interviennent au niveau des composants majeurs du grain de maïs, notamment l’amidon et les protéines, et peuvent impacter leur disponibilité. Ces modifications peuvent avoir un impact non négligeable sur l’énergie métabolisable ainsi que les performances zootechniques. Le séchage pourrait aussi affecter les propriétés physiques des grains et donc le comportement alimentaire des animaux.

Conclusions. Malgré l’importance du séchage dans la filière maïs-grain, peu d’études ont été consacrées à son effet sur la valeur nutritionnelle du maïs. Aucun consensus ne se dégage clairement sur les implications nutritionnelles de ces traitements du maïs, tant les conditions expérimentales et les méthodologies appliquées dans les travaux antérieurs varient d’une étude à l’autre. Un contrôle plus strict des conditions de séchage et l'utilisation de méthodes d'analyse adéquates s’avèrent nécessaires pour que l'effet du séchage puisse être mieux apprécié.

Abstract

Introduction. Corn is the main cereal cultivated in the world. As feedstuffs for broiler chickens, corn grains provide the majority of the animals’ required metabolizable energy and an appreciable amount of protein. However, when submitted to high temperature treatment, such as during drying, the feeding value of corn grain may change significantly. This review reports the current knowledge on changes that occur within corn grains during high temperature drying processes, which can impact on the feeding value of the grains.

Literature. Studies show that during these high temperature drying processes, structural changes occur within the major components of corn grains, including starch and proteins, which may affect their bioavailability. These changes may have a significant impact on metabolizable energy and zootechnical performance. Drying could also affect the physical traits of corn grains and in turn the feeding behavior of animals.

Conclusions. In spite of the importance of grain drying within the corn grain sector, few studies have been devoted to the effect of drying on the feeding value of corn and no consensus has been reached on this subject, possibly because of the different conditions involved in the experiments reported to date. Strict controls over drying conditions and the use of appropriate methods of analysis for a better appreciation of the effects of drying are therefore recommended.

Table des matières

1. Introduction

1Corn (Zea mays L.) is the main cereal produced in the world. It is mainly used for animal feeding and its industrial use as a raw material in the manufacture of biobased products is increasing. Indeed, corn grain has a potentially high nutritional value for livestock, making it attractive for poultry diets. Compared to wheat and barley, corn is an excellent source of carbohydrate, with low crude fiber levels and a low level of soluble non-starch polysaccharides. Corn also provides a non-negligible percentage of proteins in a broiler diet; even though these proteins are considered to be of poor quality (Cowieson, 2005).

2In many countries, corn is harvested with quite a high moisture content, which can vary between 25% and 36% (wet-basis) or even higher. To preserve their quality after harvesting, corn grains are usually dried using hot air. Most industrial dryers use air heated to between 50 and 130 °C for drying wet grain. It is generally accepted that high-temperature drying is detrimental for corn starch yield in corn fractionation and that the process may modify the structure of major components of the grain. Despite these acknowledged effects, relevant information on the effect of drying on the nutritional value of corn remains scattered, and studies performed in this field to date have failed to lead to any persuasive conclusions (Malumba et al., 2014). It is unclear whether changes induced within the corn grain affect either negatively or positively the feeding value of corn used as broiler feedstuffs. Several parameters related to the feeding value of corn grain for broilers may be impacted by heat. Among these, the proximal composition of the grain, its physical characteristics and the bioavailability of the grain’s major components are certainly the most interesting to study.

3The present review summarizes relevant previous findings on the effects of high temperature drying or similar heat-treatment on the feeding value of corn grain in the diet of broilers and other monogastrics.

2. Impact on corn grain of drying and heat treatment

2.1. Proximal composition of corn

4The proximal or chemical composition of corn is presented in feed composition tables with a great variability for each major nutrient. Such differences are usually associated with varietal differences. However, as recently demonstrated by Lasek et al. (2012), it cannot be assumed that batch-to-batch proximal content within the same corn grain cultivar will be similar. This suggests that other factors, such as the harvesting date, the drying process, the storage conditions, etc. may interfere with the proximal composition.

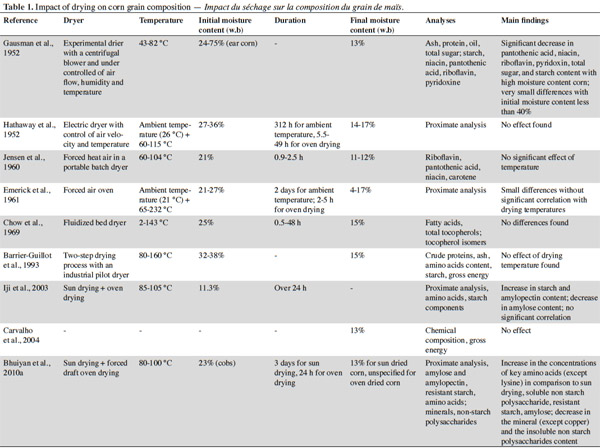

5Several studies have focused on the effect of heat treatment on the proximal composition of corn grain, or on the concentration of some particular component of nutritional interest in corn or corn-based products. Table 1 summarizes the relevant results found on the effect of drying temperature on the proximal composition of corn. A review of the results presented does not reveal any significant correlation between proximal composition and drying temperature. Chemical analyses do not appear to be very efficient in exposing differences between feedstuffs subjected to different heat treatments. Even though a chemical approach gives a description of the chemical composition of feedstuffs, it is well recognized that chemical methodologies applied to determine the proximal composition are both destructive and invasive. By looking for a specific component within a complex matrix, the chemical approach fails to link structural changes occurring inside the feedstuff matrix, which may affect the nutritional performance of the assessed component. Furthermore, the successive steps of mixing, filtering, hydrolysis, evaporation, distillation, or solvent extraction applied during the determination of the concentration of an assessed component may lead to a loss of important nutritional information about the distribution of the component inside the feedstuff matrix (Yu, 2006).

6Indeed, Malumba et al. (2014) and Gehring et al. (2012; 2013) recently observed that corn grains with a similar proximal composition may differ in their nutritional value, once submitted to different heat treatments. This phenomenon is more readily explained by changes occurring in the component structure than by their concentration in the feedstuff matrix. Moughan (2003) concluded that conventional amino acid analysis fails to detect structural changes that could have important nutritious effects.

2.2. Digestion of starch

7Starch, the major carbohydrate in corn grains is mainly located in the endosperm, and is organized in granules accumulated in concentric alternating semi-crystalline and amorphous layers (Svihus et al., 2005). Amylopectin, the highly branched component of starch, consists of chains of α-D-glucopyranosyl residues linked together mainly by 1-4 linkages, with 5 to 6% of 1-6 bonds forming branch points. Amylose is the smaller of the two fractions and possesses very few branches. The levels of amylose and amylopectin content found in a corn starch sample will depend on the variety, and these levels are fundamentally governed by genetics (Buléon et al., 1998).

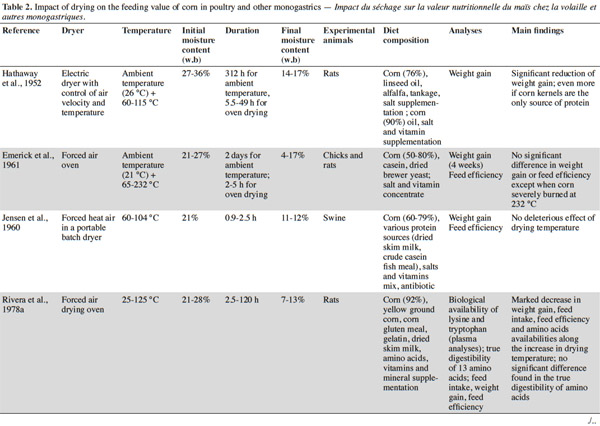

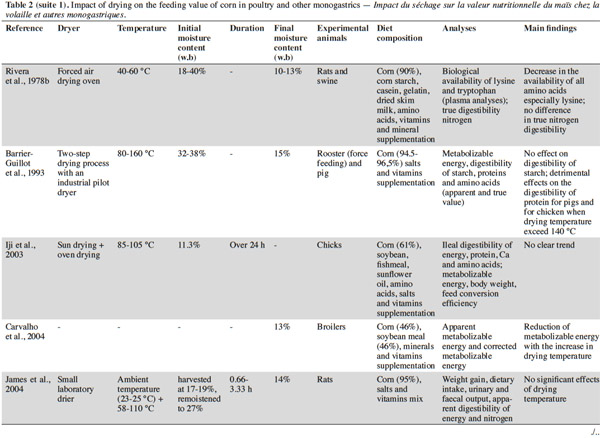

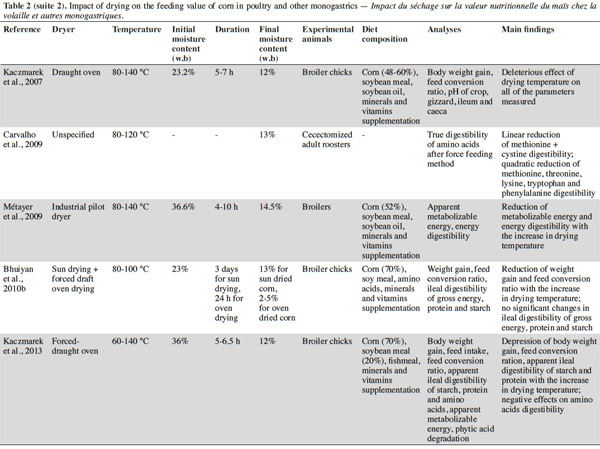

8Several factors inherent to the nature of starch and the whole corn grain such as the morphological characteristics of the starch granules (size and shape) and interactions with the surrounding compounds (starch granule associated with proteins and lipids), are thought to influence starch digestion and thus the ultimate feeding value of corn. Investigations into the effect of drying temperature on starch digestion are limited and the results reported seem contradictory (Table 2).

9Barrier-Guillot et al. (1993) and Bhuiyan et al. (2010b) reported no significant effect on the apparent digestibility of starch by broilers as a result of the drying regime and temperature. By contrast, in their study on broiler chicks, Kaczmarek et al. (2013) reported a significant decrease in the apparent ileal digestibility of starch due to the high drying temperature of corn grains consumed. The authors believed that this result was due to the formation of resistant starch during drying. Similarly, Brown (1996) also reported that such resistance increased with drying temperature. However, contrasting results were found by Iji et al. (2003), who recorded a diminution of resistant starch with a rise in the drying temperature of corn; this result may have been due to the low initial moisture content of the corn samples used in this study.

10In vitro studies have also shown different results regarding the effect of high drying temperatures. Bhuiyan et al. (2010a) reported a non-significant effect of the drying temperature, while Malumba et al. (2014) showed a significant increase in the digestibility of starch with a rise in the corn drying temperature. According to Malumba et al. (2014), the partial collapse of intra-granular structure, which occurs during the high temperature drying of the grain (pregelatinization), is probably the main factor influencing the in vitro digestibility of starch granules. In addition, the initial moisture content of corn grain seems to play a key role during the drying process, since starch pregelatinization is known to be dependent on the hydric environment (Malumba et al., 2010).

11The effect of heat moisture treatments on the digestibility of starch has been extensively studied; however, trends are not much clearer in this area. It is recognized that during heat moisture treatment, gelatinization of starch may occur. The starch granules swell; some of them burst and this results in both a loss of crystallinity and the leaching of amylose. The extent of these resulting effects depends on a range of factors, such as temperature treatment and water availability (Svihus et al., 2005). Based on previous research, Lund (1984) calculated that the water-starch ratio within rice grains needed to be higher than 0.25 in order to initiate the gelatinization of starch. Retrogradation induced after the heat treatment of grains may impact the susceptibility of starch to enzymatic digestion. Many studies have reported that gelatinization enhances the degree of starch hydrolysis, while low digestibility of starch and the formation of resistant starch are sometimes linked to retrogradation. With the extent of retrogradation depending on the amylose content of the starch granules, the subsequent digestibility observed for heat treated starch granules would vary according to the variety of grain considered.

12It could therefore be concluded that the ultimate susceptibility of corn starch to enzymatic hydrolysis is governed by the balance between gelatinization and retrogradation. Theoretically, gelatinization of starch may happen at the beginning of the high temperature drying of corn grain with a high initial moisture content, while retrogradation may occur during cooling at the end of drying. Taking into account the existing results presented in table 2, it is not possible to reach a persuasive conclusion on the effect of the drying temperature on starch structure and digestion.

2.3. Proteins and amino acids digestion

13Proteins are the second most important chemical component of the poultry diet. In common corn varieties, the protein content generally varies between 8 and 11%, dry basis (d.b). Using a sequential extraction procedure, Landry et al. (1980) reported that corn proteins may be grouped into several fractions according to their solubility in different solvents: the prolamins, which are referred to as zeins in corn (soluble in alcohol), the globulins (soluble in salt solutions), the albumins (water-soluble) and the glutelins (soluble in dilute alkaline solutions). All these families of corn protein contain a different amino acid profile, each resulting in a different nutritional significance for the broiler diet.

14Using an assay system based on ideal protein formulation with crossbred chicks, Fernandez et al. (1994) established that the limiting order in corn was as follows:

15– lysine;

16– threonine;

17– tryptophan;

18– arginine, isoleucine and valine;

19– methionine and cystine;

20– phenylalanine and tyrosine;

21– histidine.

22Based on this classification, corn proteins may be considered as having a low nutritional value. Nevertheless, these proteins can contribute to 20% of the protein requirement in a poultry starter diet (Cowieson, 2005).

23Notwithstanding the high digestibility of corn protein, it has, however, been observed that variations among samples within a cereal type may be greater than those determined between cereal types. These variations are frequently associated with cultivar, agronomy, climatic conditions and processing conditions. Some intrinsic factors of the animals considered (age, breed or strain) and dietary factors (antinutritional factors, interaction with starch) may also affect protein digestibility. Starch, non-starch polysaccharides and antinutritional factors such as polyphenols and phytic acid could interfere with protein digestion by forming an indigestible complex or a physical barrier, which either limits the access of digestive enzymes to the protein-based matrix or inactivates protease. Even though uncertainty remains, it has been proven that phytic acid may limit protein availability by forming an insoluble complex less susceptible to enzyme attack (Ravindran et al., 1999).

24During drying and heat moisture treatments, corn proteins are subjected to structural changes. Heat treatments induce non-covalent hydrophobic interactions and intermolecular disulfide crosslinks that denature corn proteins and contribute to their insolubilization. Interactions with other grain material may also occur during high temperature treatments (Malumba et al., 2008), and these can lead to a decrease in corn protein bioavailability, through the production of components resulting from Maillard reactions, for example.

25Most of the studies performed in relation to this subject, as presented in table 2, have revealed the deleterious effects of heat treatments on amino acid digestibility (Rivera et al., 1978a; Rivera et al., 1978b; Carvalho et al., 2009), and have explained this phenomenon as being a result of a Maillard reaction. Ljokjel et al. (2004) who reported similar results with a fish-meal-based diet fed to mink, however, found no changes in the amino acid profile. This suggests that other processes are involved in the decrease in amino acid digestibility. According to Mauron (1990), modifications of protein structure through the formation of secondary crosslinks or iso-peptide bonds may reduce digestibility by blocking the active sites of enzyme attack or by inducing the formation of compounds that inhibit digestive enzymes (inhibition of aminopeptidase by an advanced Maillard derivative of lysine).

26Rivera et al. (1978a) investigated the effect of drying at 40 and 60 °C on the amino acid availability of normal and opaque-2 corn fed to rats and swine. The authors observed no significant effect of drying temperature on the true digestibility of amino acids. Another study by the same authors concluded that the availability of all amino acids decreased with an increasing drying temperature. Lysine was the most sensitive amino acid, showing reductions of up to 22% for drying temperatures ranging from 40 to 60 °C. Similar trends were observed by Carvalho et al. (2009), who found a linear reduction for methionine–cystine digestibility and a quadratic decrease for methionine, threonine, lysine, tryptophan and phenylalanine digestibility with an increase in drying temperature. By contrast, Iji et al. (2003) and Bhuiyan et al. (2010b) found no effect on protein amino acid digestibility. Moreover, in their experiments with chickens, Barrier-Guillot et al. (1993) described a tendency for the level of protein digestibility to be maintained, or even to increase, between the temperature of the control treatment (drying at ambient temperature) and a moderate drying temperature (120 – 130 °C).

27Recently, Kaczmarek et al. (2013) studied the effect of forced-draught oven drying at 60, 100 and 140 °C on the digestibility of crude proteins and amino acids. The authors found that the ileal digestibility of protein and amino acids was reduced by increasing the drying temperature. This was primarily associated with a decrease in protein solubility. According to the results found by these authors, the amino acids that were most affected by the heat treatment were cysteine, tyrosine, threonine, glycine, isoleucine, serine and aspartic acid. Because of the scale of the reduction of cysteine digestibility as compared to the other amino acids, Kaczmarek et al. (2013) argued that protein insolubilization and disulfide bond formation during heating were the most important processes affecting corn protein digestibility. However, the mechanisms involved in the denaturation of protein during drying and heat treatments are still unclear.

28Kaczmarek et al. (2013) asserted that as a consequence of the decrease in protein digestibility with the increase in drying temperature, animals fed with corn dried at higher temperatures would increase their secretion of pepsin and HCl production in the gastric phase of digestion. In order to compensate for this impairment of protein digestibility, the animals would regulate their secretion of proteolytic enzymes, providing more protease during the intestinal phase of digestion, to the detriment of other nitrogen metabolism schemes. However, such a physiological regulation may affect the performance of animals. Nevertheless, the relationship between protein denaturation and the growth performance of broilers has been little investigated (Gehring et al., 2012).

2.4. Metabolization of energy provided by corn-based feedstuffs and its effect on broiler performance

29Corn is mainly used in poultry diets as a source of energy. Apparent metabolizable energy (AME) and true metabolizable energy (TME) are the principal criteria used to characterize the availability of energy in corn. The whole corn kernel contains on average 3,500 kcal·kg-1 (d.b) of AME. The variation in AME from batch to batch may be significant, and higher than 500 kcal·kg-1 (Cowieson, 2005). The ratio of available energy to gross energy is higher for corn than for other cereals (wheat, barley, oats) due to its relatively high starch content (620 to 720 g·kg-1, d.b) and crude fat content (34 to 52 g·kg-1 d.b) (Lasek et al., 2012).

30The effects of drying temperature on energy provided by cornstuffs are difficult to discuss, as there is a great variability in the determined parameters and the methodologies applied. Iji et al. (2003) and Bhuiyan et al. (2010b) examined, in a broiler growth trial, the effect of drying corn at a high temperature on the ileal digestibility of gross energy, and found no significant effect. Similar results were also obtained by James et al. (2004) with a growing rat assay. Barrier-Guillot et al. (1993) unexpectedly reported a positive effect of drying on metabolizable energy, with a slight increase in the true metabolizable energy of corn grain dried below 140 °C. By contrast, Carvalho et al. (2004), Metayer et al. (2009) and Kaczmarek et al. (2013) described a reduction of up to 100 kcal·kg-1 (d.b) of AME due to lower ileal starch and protein digestibility as a consequence of drying at high temperatures.

31The combination of the effect of drying temperature on energy, starch and proteins has possible implications for animal performance. The effects of drying on feed intake and weight gain have been studied for rats, chicks and swine (Table 2). A decrease in feed intake and weight gain has been noted for assays with rats and chicks, but not for those with swine, perhaps because of the robustness of the digestive tract in these animals. Hathaway et al. (1952) investigated the effect of drying ears of corn with hot air on weight gain within rats fed individually for eight weeks. The authors reported a reduction in weight gain accompanied by a cut in feed intake, especially when corn was used as a protein source. Grain dried at higher temperatures seemed to be less acceptable to the rats; however, this had no impact on weight gain per feed unit. These observations stand in contrast to those of Rivera et al. (1978a), Iji et al. (2003), Kaczmarek et al. (2007), Bhuiyan et al. (2010b) and Kaczmarek et al. (2013), who reported a negative impact of high temperature drying on weight gain. Rivera et al. (1978a) associated these findings with a deterioration in the quality of corn protein. In an experiment using high-quality protein ingredients in combination with dried corn, Emerick et al. (1961) reported no deleterious effect caused by drying temperature, thus supporting the hypothesis that this depressive effect on weight gain may be overcome by supplementation with amino acids. On the other hand, James et al. (2004) found no effect of the drying temperature on rats fed with a diet almost entirely composed of dried corn (95%). This suggests that other confounding factors may be involved.

2.5. Physical traits that may interfere with grain component ingestion and digestion

32Although the formulation of a broiler diet is based on the evaluation of the nutritional value of the feed, it is important to take into account the physical traits of the grains used, since chicks (beyond the food intake behavior of the strains considered) mainly peck according to these factors. In the case of broilers, the main physical traits that are susceptible to impacting ingestion are related to the particle size (touch) and color (vision) of the feed (Picard et al., 1999).

33Feed particle size has increasingly been a focus of interest since it is known to be associated with the development of the gizzard, and with gut motility and the digestion of nutrients. Recommendations regarding optimum feed particle size, however, have been contradictory, as the results from feeding trials have been confounded by a number of factors, including the vitreousness of feed endosperm (Amerah et al., 2007). Vitreousness (sometimes called hardness) – often referred to as the ratio between the amount of vitreous (or hard) endosperm and the amount of floury (or soft) endosperm – is an important physical characteristic of the corn kernel, which affects its milling quality.

34It has been found that increasing vitreousness leads to a decrease in in vitro dry matter and starch digestibility but, as demonstrated by Gehring et al. (2013), this has little effect on broiler performance. It is also believed that corn hardness influences the extent of endosperm damage during high temperature drying, which is less pronounced for hard endosperm (Kaczmarek et al., 2013). Interactions between drying process and vitreousness have also been previously established as the cause of an increase in internal fissures in corn endosperm (stress cracks) and breakage susceptibility (much higher for soft varieties) with an increase in drying temperature. It is possible that this impacts digestion, since an increase in internal fissures could ease the entry of moisture (and thus enzymes) into the corn endosperm, leading to a higher level of degradation. However, as stated by Mayolle et al. (2012), a better diffusion of water and enzymes does not seem to be a limiting factor in enzyme activity. Considering that endosperm hardness may impact feed particle size distribution, it would therefore be possible to link drying temperature to particle size distribution and, in turn, to feed ingestion. One might also speculate whether the color of the feed particle may impact ingestion as it is well known that the color of corn grain is influenced by the drying temperature (Odjo et al., 2012). Unfortunately, these proposals are only assumptions, due to the scarcity of information regarding the impact of drying on physical traits that may interfere with grain component ingestion and digestion.

3. Way to improve the comprehensive effect of heat or drying treatment of corn grain on its nutritive value

35Comparison of the results presented is difficult because the drying conditions are quite different in each study cited. According to Jimenez-Moreno et al. (2009), these differences could arise from the varieties considered and the conditions applied during the drying process. Furthermore, drying is a complex process and its effect depends on many parameters, including the initial moisture content of the grain, the type of dryer used, the heat drying process (one or two different drying temperatures) and the drying time (Barrier-Guillot et al., 1993).

36In order to assess the effect of drying temperature on the nutritive value of cornstuffs, a well-controlled experimental scheme needs to be performed. It is our belief that among the parameters that must be controlled, the following are critical: the initial moisture content of corn grain, the drying temperature, and ventilation inside the dryer.

3.1. Control of ventilation and drying temperature during sample drying

37In order to allow a safe comparison of the effect of drying, the system used must insure proper ventilation and heat homogenization inside the dryer. Oven dryers do not always ensure good temperature homogeneity or a rapid increase in grain temperature and there is a risk that the drying air will follow preferential paths. This may also explain the long drying time frequently recorded when oven drying is used, even at temperatures above 100 °C. More efficient systems such as a spouted bed or a fluidized bed would be more suitable for this kind of comparison. According to Janas et al. (2010), the rise in corn grain temperature during fluidized bed drying takes place very quickly.

3.2. Control of the initial moisture content of the grain

38Another important factor is the initial moisture content of corn before the drying process. In comparing their results with those of Iji et al. (2003), Kaczmarek et al. (2007) found that adverse effects of drying were correlated with high moisture content corn. They argued that starch and other polysaccharides in high moisture corn may undergo partial degradation during the pre-drying period, increasing the reducing sugar concentration and thus promoting Maillard reactions during drying.

39Gausman et al. (1952) also pointed out that the effects of drying temperature were more noticeable in the case of an initial moisture content of higher than 40%, while Rivera et al. (1978a; 1978b) added that corn with a high moisture content is more susceptible to protein damage as a result of heat treatment. This might explain the fact that Iji et al. (2003), who used samples with an initial moisture content of 11%, found no deleterious effect of drying temperature. The importance of the initial moisture content seems, therefore, to be found in the appraisal of the effect of drying, especially since corn protein denaturation caused by heat stress during drying and heat treatment may continue at a low moisture content. And this is even more the case with an increase in temperature (Odjo et al., 2012).

4. Conclusions

40Based on the findings highlighted in this review, corn may be considered to be a suitable cereal source for poultry. However, the feeding value of this grain varies significantly depending on various conditions, such as starch structure and its interaction with its adjacent components, and drying and heat processing. A review of studies performed in order to elucidate the effect of drying temperature on the feeding value of corn for poultry does not lead to any persuasive conclusions. This kind of experimentation must take into account factors such as moisture content, corn type, thermal history and experimental conditions, all of which are susceptible to influencing results. Furthermore, complementary studies are needed to determine the biochemical, structural or physical and chemical changes occurring in grain components, which could modify their nutritive value.

41Acknowledgements

42This research was funded by the “Direction Génerale Opérationnelle de l’Agriculture, des Ressources Naturelles et de l’Environnement” of the Walloon Government through the project MAISECVOL. Financial support for Mr Odjo was provided by “Wallonie Bruxelles International (WBI)”. The authors are grateful to Mrs L. Doran for her assistance.

Bibliographie

Amerah A.M., Ravindran V., Lentle R.G. & Thomas D.G., 2007. Feed particle size: implications on the digestion and performance of poultry. World’s Poult. Sci. J., 63, 439-455.

Barrier-Guillot B. et al., 1993. Effect of heat drying temperature on the nutritive value of corn in chickens and pigs. Anim. Feed Sci. Technol., 41, 149-159.

Bhuiyan M.M., Islam A.F. & Iji P.A., 2010a. Variation in nutrient composition and structure of high-moisture maize dried at different temperatures. S. Afr. J. Anim. Sci., 40, 190-197.

Bhuiyan M.M., Islam A.F. & Iji P.A., 2010b. Response of broiler chickens to diets containing artificially dried high-moisture maize supplemented with microbial enzymes. S. Afr. J. Anim. Sci., 40, 348-362.

Buléon A., Colonna P., Planchot V. & Ball S., 1998. Starch granules: structure and biosynthesis. Int. J. Biol. Macromol., 23, 85-112.

Brown I., 1996. Complex carbohydrates and resistance starch. Nutr. Rev., 54, S115-S119.

Carvalho D.C.O. et al., 2004. Chemical and energy composition of corn sample under different drying temperature and storage periods. (Portuguese). Rev. Bras. Zootecn., 35, 358-364.

Carvalho D.C.O. et al., 2009. True digestibility of amino acids and digestible amino acids values of corn samples submitted to different drying temperatures and storage periods. (Portuguese). Rev. Bras. Zootecn., 38, 850-856.

Chow C.K. & Draper H.H., 1969. Effect of artificial drying on tocopherols and fatty acids of corn. J. Agric. Food Chem., 17, 1316-1317

Cowieson A.J., 2005. Factors that affect the nutritional value of maize for broilers. Anim. Feed Sci. Technol., 119, 293-305.

Emerick R.J., Carlson C.W. & Winterfeld H.L., 1961. Effect of heat drying upon the nutritive value of corn. Poult. Sci., 40, 991-995.

Fernandez S.R. et al., 1994. Limiting order of amino acids in corn and soybean meal for growth of the chick. Poult. Sci., 73, 1887-1896.

Gausman H.W. et al., 1952. Some effects of artificial drying of corn grain. Plant Physiol., 27, 794-802.

Gehring C.K., Bedford M.R., Cowieson A.J. & Dozier W.A. 3rd, 2012. Effects of corn source on the relationship between in vitro assays and ileal nutrient digestibility. Poult. Sci., 91, 1908-1914.

Gehring C.K., Cowieson A.J., Bedford M.R. & Dozier W.A. III, 2013. Identifying variation in the nutritional value of corn based on chemical kernel characteristics. World’s Poult. Sci. J., 69, 299-312.

Hathaway I.L., Yung F.D. & Kiesselbach T.A., 1952. The effect of drying temperature upon the nutritive value and commercial grade of corn. J. Anim. Sci., 11, 430-440.

Iji P., Khumalo K., Slippers S. & Gous R., 2003. Intestinal function and body growth of broiler chickens on diets based on maize dried at different temperatures and supplemented with a microbial enzyme. Reprod. Nutr. Dev., 43, 77-90.

James K. et al., 2004. The effect of drying room temperature on the nutritional quality of New Zealand-grown maize for growing rats. J. Sci. Food Agric., 84, 147-157.

Janas S., Malumba P., Deroanne C. & Béra F., 2010. Comparaison d’un modèle empirique et d’un modèle physique de séchage de grains de maïs en lit fluidisé. Biotechnol. Agron. Soc. Environ., 14(3), 389-398.

Jensen A.H., Terrill S.W. & Becker D.E., 1960. Nutritive value of corn dried at 140, 180 and 220 farenheit for swine of different ages. J. Anim. Sci., 19, 629-638.

Jimenez-Moreno E., Gonzalez-Alvarado J.M., Lazaro R. & Mateos G.G., 2009. Effects of type of cereal, heat processing of the cereal, and fiber inclusion in the diet on gizzard pH and nutrient utilization in broilers at different ages. Poult. Sci., 88, 1925-1933.

Kaczmarek S. et al., 2007. The effect of drying temperature and exogenous enzymes supplementation on the nutritional value of maize for broiler chickens. In: Proceedings of the 16th European Symposium on poultry nutrition, August 26-30, 2007, Strasbourg, France, 555-558.

Kaczmarek S., Cowieson A.J., Jozefiak D. & Rutkowski A., 2013. Effect of maize endosperm hardness, drying temperature and microbial enzyme supplementation on the performance of broiler chickens. Anim. Prod. Sci., 54, 956-965.

Landry J. & Moureaux T., 1980. Distribution and amino-acid composition of protein groups located in different histological parts of maize grain. J. Agric. Food Chem., 28, 1186-1191.

Lasek O. et al., 2012. The nutritive value of maize cultivars for broiler chickens. J. Anim. Feed Sci., 21, 345-360.

Ljokjel K., Sorensen M., Storebakken T. & Skrede A., 2004. Digestibility of protein, amino acid and starch in mink (Mustela vison) fed diets processed by different extrusion conditions. Can. J. Anim. Sci., 84, 673-680.

Lund D., 1984. Influence of time, temperature, moisture, ingredients and processing conditions on starch gelatinization. Crit. Rev. Food Sci. Nutr., 20, 249-273.

Malumba P., Vanderghem C., Deroanne C. & Béra F., 2008. Influence of drying temperature on the solubility, the purity of isolates and the electrophoretic patterns of corn proteins. Food Chem., 111, 564-572.

Malumba P. et al., 2010. Comparative study of the effect of drying temperatures and heat-moisture treatment on the physicochemical and functional properties of corn starch. Carbohydr. Polym., 79, 633-641.

Malumba P. et al., 2014. Physicochemical characterization and in vitro assessment of the nutritive value of starch yield from corn dried at different temperatures. Starch/Staärke, 66, 1-11.

Mauron J., 1990. Influence of processing on protein quality. J. Nutr. Sci. Vitaminol., 36, S57-S69.

Mayolle J.E. et al., 2012. Water diffusion and enzyme activities during malting of barley grains: a relationship assessment. J. Food Eng., 109, 358-365.

Métayer J.P., Debicki-Garnier A.-M. & Skiba F., 2009. Le Promatest : un bon indicateur de la qualité du séchage et de la valeur alimentaire du maïs grain chez les volailles. In : Huitièmes Journées de la Recherche Avicole, 25-26 mars, St Malo, France.

Moughan P.J., 2003. Amino acid availability: aspects of chemical analysis and bioassay methodology. Nutr. Res. Rev., 16, 127-141.

Odjo S. et al., 2012. Influence of drying and hydrothermal treatment of corn on the denaturation of salt-soluble proteins and color parameters. J. Food Eng., 109, 561-570.

Picard M., Plouzeau M. & Faure J.M., 1999. A behavioural approach to feeding broilers. Ann. Zootech., 48, 233-245.

Ravindran V., Cabahug S., Ravindran G. & Bryden W.L., 1999. Influence of microbial phytase on apparent ileal amino acid digestibility of feedstuffs for broilers. Poult. Sci., 78, 699-706.

Rivera P.H. et al., 1978a. Effect of maturity and drying temperature on nutritional quality and amino acid availability of normal and opaque-2 corn for rats and swine. J. Anim. Sci., 46, 1024-1036.

Rivera P.H. et al., 1978b. Effect of drying temperature on nutritional quality and availability of amino acids in normal and opaque-2 corn for rats. J. Anim. Sci., 46, 1275-1286.

Svihus B., Uhlen A.K. & Harstad O.M., 2005. Effect of starch granule structure, associated components and processing on nutritive value of cereal starch: a review. Anim. Feed Sci. Technol., 122, 303-320.

Yu P., 2006. An emerging method for rapid characterization of feed structures and feed component matrix at a cellular level and relation to feed quality and nutritive value. Arch. Anim. Nutr., 60, 229-244.